Since 2005 / One stop supplier

Frp anchor bolts are high-strength bolts made of fiber-reinforced polymer (FRP) materials that are used to anchor structural elements to concrete. They have man

Customized service:

Diameter

Color

Length

Winding method

Surface Sandblasting

Punch hole

Frp anchor bolts can be used forvarious applications, such as:

Strengthening existing concrete structures with FRP plates or wraps

Types of Frp Anchor Bolts

There are two main types of frp anchor bolts: field-laminated and pre-fabricated.

Field-Laminated Frp Anchor Bolts

Field-laminated frp anchor bolts are made by wrapping FRP fabric around a steel core and curing it with resin on site. They can be customized to fit any shape or size of the hole and can carry load into the concrete to improve bond strength, or through the concrete to transfer load for increased capacity. They are available in carbon and E-glass fibers, with diameters ranging from 1/4" (6.4 mm) to 1 1/2" (38.1 mm) in custom lengths.

Pre-Fabricated Frp Anchor Bolts

Pre-fabricated frp anchor bolts are made by molding FRP material around a steel core in a factory. They have a standard hex head and a flange that distributes pressure where the bolt meets the surface, eliminating the need for a separate washer. They are chemical and oil resistant, nonconductive, and lightweight. They have diameters ranging from 1/4" (6.4 mm) to 3/4" (19.1 mm) and lengths ranging from 1/2" (12.7 mm) to 5" (127 mm).

Performance and Parameters of Frp Anchor Bolts

The performance and parameters of frp anchor bolts depend on the type, material, diameter, length, spacing, and installation method of the bolts. Some general guidelines are:

The following table shows some examples of the performance and parameters of frp anchor bolts based on experimental studies:

| Type | Material | Diameter | Length | Spacing | Load Capacity |

| Field-laminated | Carbon fiber | 12.7 mm | 300 mm | 100 mm x 38 mm | 206 kN |

| Pre-fabricated | Glass fiber | 15.9 mm | 76.2 mm | 50.8 mm x 50.8 mm | 44 kN |

We are both manufacturer trading and company. We have our own factory and we have better service ofoverseas customers. Welcome to send your inquiry!

We can supply a few pieces FREE samples if we have some in stock, and you only need to pay the freight cost by yourself. Welcome to send your inquiry for FREE samples!

10-15days after receiving the deposit based on the MOQ. Normally, 30-35days to finish the order for a 20ft container. Welcome to ask for the detailed delivery time according to your order quantity!

Our whole production lines and products have been certificated by IS09001:2015, and it's been followed strictly. We also have the professional QC team, and each our package worker will be in charge of the final inspection according to the QC instruction before packing.

Basically, the payment terms areT/T,L/C at sight. Western Union, Paypal, Moneygram, Alipay Credit card are acceptableforsample order.

We accept all OEM orders,just contact us and give me your design,we will offer you a reasonable price ASAP.

Flexible fiberglass rods for flags are a type of flagpole that is made of fiberglass, a strong and lightweight material. The rods are flexible, which means that they can bend without breaking, making them ideal for areas with high winds. They are also lig

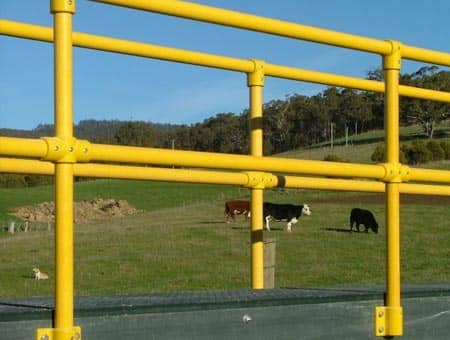

Composite retaining walls are a new type of retaining wall that combines the advantages of steel reinforced concrete (RC) and fiber reinforced polymer (FRP) materials. FRP materials have high strength, corrosion resistance, and light weight, which make th

Characteristics of Fiberglass Round Pipe, Fiberglass round pipe is a material composed of glass fiber and resin, which has the following characteristics

Pedestrian bridges are structures that provide safe and convenient access for pedestrians, cyclists, equestrians, and other non-motorized users across various obstacles, such as roads, railways, rivers, or valleys. Pedestrian bridges can also enhance the

The quality of the product is very good, all performance tests have passed, and the service attitude of the docking staff is very good

ClydeEngineer, From india

Compared with our local products, the quality of this batch of profiles is quite good, it is worth recommending

DevinCEO, From Germany

The engineer has comprehensive professional knowledge, answered many questions, and put forward many useful suggestions, which made the plan more perfect

AaronCTO, From Mexico

Quote

Email: Jessica@frpzs.com

Phone

Phone+86-15303735673

WhatsApp

+86-15303735673

WeChat

+86-15303735673