Application of FRP customized pultruded profiles in Chain Scraper Systems - Sewage Treatment

As an engineer specializing in wastewater treatment systems, I have witnessed the transformative impact of Fiber-Reinforced Polymer (FRP) customized pultruded profiles. These versatile materials play a crucial role in enhancing the efficiency, durability, and sustainability of sewage treatment processes. In this article, I’ll delve into the significance of FRP profiles specifically within Chain Scraper Systems and their applications in sewage treatment facilities.

Understanding FRP Profiles

Before we explore their applications, let’s clarify what FRP profiles are:

Key Benefits of FRP Profiles in Chain Scraper Systems

1. Durability and Corrosion Resistance

Corrosion Resistance: Unlike traditional materials such as steel, FRP profiles do not rust or degrade when exposed to aggressive chemicals and moisture. This property is critical in sewage treatment plants where harsh conditions prevail.

Longevity: FRP profiles offer extended service life, minimizing maintenance costs and replacement hassles.

2. Lightweight and High Strength

Efficient Installation: The lightweight nature of FRP profiles simplifies installation and reduces the load on supporting structures.

System Performance: In Chain Scraper Systems, where components need to move smoothly, FRP’s strength-to-weight ratio ensures optimal performance.

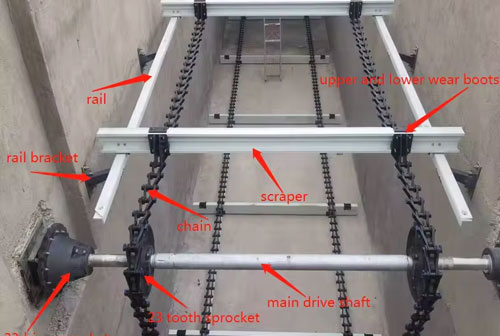

Application of FRP customized pultruded profiles in Chain Scraper Systems - Sewage Treatment

3. Chemical Resistance

Versatility: FRP profiles exhibit excellent resistance to acids, alkalis, and other chemicals commonly encountered in sewage treatment facilities.

Reliable Operation: Their ability to withstand aggressive substances ensures reliable system operation over time.

4. Customization and Design Flexibility

Tailored Solutions: Manufacturers can customize FRP profiles based on specific project requirements. Shape, size, and mechanical properties can be adjusted to optimize system design.

Efficient Sludge Removal: Custom profiles enhance scraping efficiency, ensuring effective removal of sludge and debris.

5. Non-Conductive Properties

Electrical Safety: FRP is an excellent electrical insulator. In sewage treatment systems, where electrical hazards exist, FRP profiles prevent conductivity, minimizing risks to workers.

6. Cost-Effectiveness

Long-Term Benefits: Although FRP profiles may have higher initial costs, their durability, reduced maintenance, and improved system performance make them cost-effective in the long run.

Conclusion

In summary, the application of FRP customized pultruded profiles in Chain Scraper Systems significantly contributes to the reliability and efficiency of sewage treatment processes. Collaborating with material suppliers and molders ensures optimal utilization of FRP profiles for specific project needs.

FRP Profiles

Remember, as engineers, we have the power to transform wastewater treatment systems, and FRP profiles are a vital tool in achieving cleaner, more sustainable environments.

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data