Composite Sleepers

Composite sleepers and concrete sleepers are two common types of railway sleepers. They each have advantages and disadvantages that make them more or less suitable for different applications. This article will compare the two types of sleepers and discuss their environmental impact.

What are Composite Sleepers?

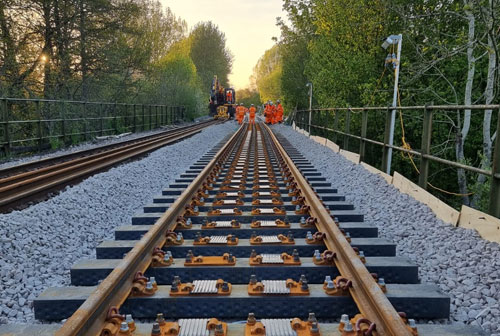

Composite sleepers are made from a combination of materials, including fiberglass, carbon fiber, and recycled plastic. They are designed to be strong, durable, and low maintenance. Composite sleepers are also lightweight, which makes them easier to transport and install than concrete sleepers.

What are Concrete Sleepers?

Concrete sleepers are made from concrete, a mixture of cement, water, and aggregates. They are strong and durable, but they are also heavy and difficult to transport and install. Concrete sleepers are also more susceptible to cracking and breaking than composite sleepers.

Advantages of Composite Sleepers:

Durability: Composite sleepers are designed to last for many years, even in harsh environments. They are resistant to rotting, cracking, and insect damage. Low maintenance: Composite sleepers require very little maintenance. They do not need to be treated or painted, and they can be easily cleaned with a power washer. Lightweight: Composite sleepers are much lighter than concrete sleepers, which makes them easier to transport and install. This can save time and money on construction costs. Environmental impact: Composite sleepers are made from recycled materials, which reduces their environmental impact. They also do not require the use of creosote, a toxic chemical that is often used to treat wooden sleepers.

Disadvantages of Composite Sleepers:

Cost: Composite sleepers are more expensive than concrete sleepers. However, their long lifespan and low maintenance requirements can offset the initial cost. Fire resistance: Composite sleepers are not as fire-resistant as concrete sleepers. This may be a consideration for railways that operate in areas with a high risk of wildfires.

Advantages of Concrete Sleepers:

Cost: Concrete sleepers are less expensive than composite sleepers. This makes them a more affordable option for railways with limited budgets. Strength: Concrete sleepers are very strong and can support heavy loads. This makes them ideal for use in high-traffic areas. Fire resistance: Concrete sleepers are fire-resistant, which makes them a good choice for railways that operate in areas with a high risk of wildfires.

Disadvantages of Concrete Sleepers:

Weight: Concrete sleepers are very heavy, which makes them difficult to transport and install. This can add to the cost of construction. Maintenance: Concrete sleepers require regular maintenance. They need to be inspected for cracks and breaks, and they need to be replaced more often than composite sleepers. Environmental impact: The production of concrete sleepers produces a significant amount of carbon dioxide. This contributes to climate change.

Environmental Impact of Composite Sleepers vs. Concrete Sleepers:

The production of concrete sleepers has a significant environmental impact. Concrete is a major source of greenhouse gases, and its production consumes a lot of energy and water. Composite sleepers, on the other hand, are made from recycled materials and have a much lower environmental impact.

Conclusion:

Composite sleepers and concrete sleepers are both viable options for railway construction. The choice of which type to use depends on the specific needs of the project. Composite sleepers are a good choice for projects that require a durable, low maintenance, and environmentally friendly sleeper. Concrete sleepers are a good choice for projects that require a strong and affordable sleeper.

Contact Us:

If you are looking for Composite sleepers, contact Henan Zhongsheng today. We can help you choose the right type of sleeper for your project and provide you with a quote.

+86-15303735673

+86-15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data