Fiber-Reinforced Polymer (FRP) pultruded composite materials are gaining popularity in various industries due to their superior properties. The continuous pultrusion process plays a crucial role in the manufacturing of these materials.

The Pultrusion Process

The pultrusion process is a method of manufacturing linear composite materials with constant cross-sections. It involves pulling raw materials (resin and reinforcements) through a heated die where the resin undergoes polymerization.

Steps in the Pultrusion Process

Preparation: The process begins with the preparation of reinforcement fibers, which are pulled from creels and guided into a resin bath for impregnation.

Resin Impregnation: The fibers are thoroughly wetted with the resin mixture, ensuring that all fibers are impregnated.

Preforming: The impregnated reinforcements are then gathered and guided through a preforming system to create the desired profile before entering the heated die.

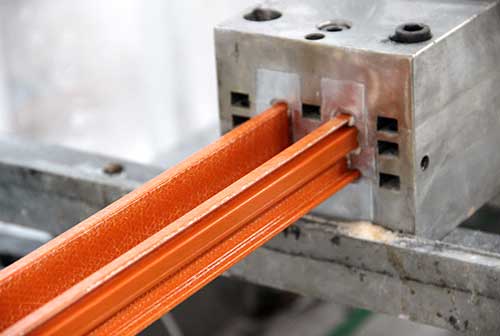

Curing: As the materials pass through the heated die, the resin cures and hardens, taking on the shape of the die.

Cutting: The cured profile is continuously pulled out of the die and cut into desired lengths.

Advantages of Continuous Pultrusion

The continuous pultrusion process offers several advantages:

Efficiency: It allows for continuous production, leading to high efficiency and productivity.

Versatility: A wide range of profiles can be produced, including rods, tubes, channels, and custom profiles.

Quality: The process results in products with high strength-to-weight ratio, excellent corrosion resistance, and superior dimensional stability.

Applications of FRP Pultruded Composites

FRP pultruded composites have found applications in various industries:

Construction: Used in the construction of bridges, buildings, and other structures due to their high strength and corrosion resistance.

Electrical: Used in electrical insulation applications because of their excellent electrical insulating properties.

Transportation: Used in the manufacture of lightweight parts for automotive and aerospace applications.

Conclusion

In conclusion, the continuous pultrusion process is an efficient and versatile method for producing FRP pultruded composite materials. These materials offer numerous benefits over traditional materials, making them a popular choice in various industries.

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data