Composite materials are made of two or more different materials that are combined to create a new material with enhanced properties. Composite profiles are structural elements that have a cross-sectional shape and are used in various applications, such as construction, aerospace, automotive, and sports equipment. Two common types of composite profiles are fiberglass composite profiles and carbon fiber composite profiles, which differ in their composition, properties, and advantages.

Fiberglass Composite Profiles

Fiberglass composite profiles are made of glass fibers embedded in a polymer matrix, such as epoxy, polyester, or vinyl ester. The glass fibers provide strength and stiffness to the composite, while the polymer matrix protects the fibers from environmental damage and binds them together. Fiberglass composite profiles have several advantages, such as:

Low cost: Fiberglass composite profiles are cheaper than carbon fiber composite profiles, as glass fibers are more abundant and less expensive than carbon fibers.

Corrosion resistance: Fiberglass composite profiles are resistant to corrosion from chemicals, moisture, and salt water. This makes them suitable for applications in marine environments, such as boat hulls, masts, and propellers.

Electrical insulation: Fiberglass composite profiles are non-conductive and can insulate electrical currents. This makes them suitable for applications in electrical and electronic industries, such as transformers, circuit boards, and antennas.

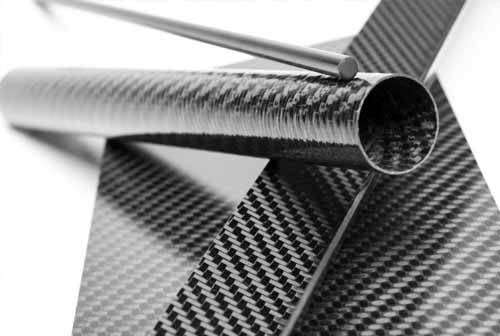

Carbon Fiber Composite Profiles

Carbon fiber composite profiles are made of carbon fibers embedded in a polymer matrix, such as epoxy, polyester, or vinyl ester. The carbon fibers provide high strength and stiffness to the composite, while the polymer matrix protects the fibers from abrasion and impact. Carbon fiber composite profiles have several advantages, such as:

High strength-to-weight ratio: Carbon fiber composite profiles have a higher strength-to-weight ratio than fiberglass composite profiles, as carbon fibers are stronger and lighter than glass fibers. This makes them suitable for applications that require high performance and low weight, such as aerospace, automotive, and sports equipment.

High thermal conductivity: Carbon fiber composite profiles have a higher thermal conductivity than fiberglass composite profiles, as carbon fibers can transfer heat more efficiently than glass fibers. This makes them suitable for applications that require heat dissipation or temperature regulation, such as heat sinks, radiators, and cooling systems.

High fatigue resistance: Carbon fiber composite profiles have a higher fatigue resistance than fiberglass composite profiles, as carbon fibers can withstand repeated loading and unloading without losing their strength. This makes them suitable for applications that require durability and reliability, such as bridges, wind turbines, and prosthetics.

Conclusion

Fiberglass composite profiles and carbon fiber composite profiles are two types of composite materials that have different properties and advantages. Fiberglass composite profiles are cheaper, corrosion resistant, and electrically insulating. Carbon fiber composite profiles are stronger, lighter, thermally conductive, and fatigue resistant. Depending on the application requirements and budget constraints, one type of composite profile may be more suitable than the other. Therefore, it is important to compare the characteristics of both types of composite profiles before choosing the best option.

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data