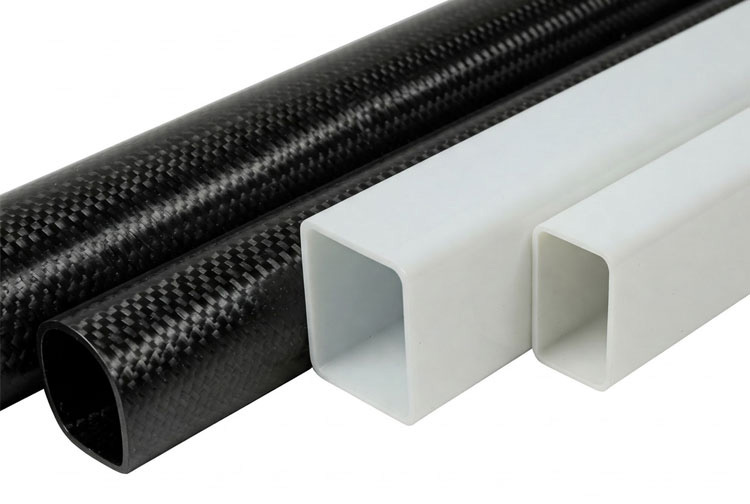

carbon fibre reinforced polymer vs Glass fibre reinforced polymer

When it comes to selecting the ideal composite material for a specific application, carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) are often at the forefront of consideration. Both materials offer unique properties and advantages, making the choice dependent on the particular requirements of the project. This article will delve into the key differences between CFRP and GFRP to help you make an informed decision.

Understanding Composite Materials

Before diving into the comparison, let's briefly define what composite materials are. Composites consist of two or more materials combined to achieve properties that are superior to those of the individual components. In the case of CFRP and GFRP, the reinforcement is provided by fibers (carbon or glass), while the matrix is typically a polymer resin.

CFRP: The High-Performance Option

Properties: CFRP boasts exceptional strength-to-weight ratio, high stiffness, excellent corrosion resistance, and outstanding dimensional stability.

Applications: Aerospace, automotive, sporting goods, and high-performance engineering applications.

Advantages: Lightweight, strong, durable, and can be tailored to specific performance requirements.

Disadvantages: High cost, complex manufacturing processes, and potential electrical conductivity.

GFRP: The Versatile Choice

Properties: GFRP offers good strength, excellent chemical resistance, and is relatively easy to mold and shape.

Applications: Construction, marine, automotive, and chemical processing industries.

Advantages: Cost-effective, versatile, and easy to manufacture.

Disadvantages: Lower strength-to-weight ratio compared to CFRP, and can be susceptible to UV degradation.

Key Differences Between CFRP and GFRP

| Feature | CFRP | GFRP |

| Strength | Very high | High |

| Stiffness | Very high | High |

| Weight | Lightweight | Relatively lightweight |

| Cost | High | Moderate |

| Corrosion resistance | Excellent | Excellent |

| Electrical conductivity | Conductive | Non-conductive |

| Manufacturing complexity | High | Moderate |

Factors to Consider When Choosing Between CFRP and GFRP

Performance requirements: Strength, stiffness, weight, and durability.

Cost: Material cost, manufacturing cost, and overall project cost.

Environmental conditions: Exposure to chemicals, temperature, and UV radiation.

Aesthetics: Surface finish and appearance.

Manufacturing capabilities: Availability of equipment and expertise.

Applications and Case Studies

Aerospace: CFRP is extensively used in aircraft structures due to its high strength-to-weight ratio.

Automotive: Both CFRP and GFRP find applications in automotive components, such as body panels and chassis.

Marine: GFRP is commonly used for boat hulls and other marine structures due to its corrosion resistance.

Construction: GFRP is used for reinforcing concrete and creating lightweight structures.

Conclusion

The choice between CFRP and GFRP ultimately depends on the specific requirements of your project. If you prioritize high strength, stiffness, and weight savings, CFRP is an excellent choice. However, if cost and ease of manufacturing are primary concerns, GFRP may be a more suitable option. By carefully considering the factors discussed in this article, you can make an informed decision and select the composite material.

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data