FRP profile pultrusion process

Introduction:

In the world of fiberglass pultrusion, mold blockages pose a significant challenge that can disrupt production, lead to product defects, and increase costs. Understanding the causes and consequences of these blockages is crucial for manufacturers to implement preventive measures and maintain a streamlined production process.

Causes of Mold Blockage in Fiberglass Pultrusion:

1. Resin Gelation: Resin gelation occurs when the resin prematurely cures within the mold, causing it to solidify and adhere to the mold surfaces. This can be triggered by several factors, including:

· High resin temperature: Elevated resin temperatures accelerate the curing process, increasing the likelihood of gelation within the mold.

· Inconsistent resin viscosity: Variations in resin viscosity can lead to uneven curing rates, potentially causing gelation in specific areas of the mold.

· Slow pultrusion speed: If the pultrusion speed is too slow, the resin may have excessive time to cure within the mold, resulting in blockages.

2. Fiber Debris Accumulation: Fiber debris, generated during the pultrusion process, can accumulate within the mold, gradually restricting the flow of resin and eventually causing blockages. This debris can originate from:

· Improper fiber preparation: Inadequate fiber cleaning or the presence of contaminants can introduce fiber debris into the pultrusion process.

· Inefficient mold design: Molds with sharp corners or inadequate drainage channels can trap fiber debris, leading to blockages over time.

· Wear and tear on mold components: Over time, mold components, such as guides and rollers, can wear down, generating debris that contributes to blockages.

3. Foreign Matter Contamination: The introduction of foreign matter, such as dust, dirt, or airborne contaminants, into the pultrusion process can lead to mold blockages. This contamination can arise from:

· Unsanitary work environment: A dusty or unclean work environment can introduce contaminants into the pultrusion area.

· Improper material handling: Careless handling of raw materials, such as fiberglass roving or resin, can introduce contaminants into the process.

· Inadequate mold cleaning: Incomplete or infrequent mold cleaning can allow contaminants to accumulate within the mold, leading to blockages.

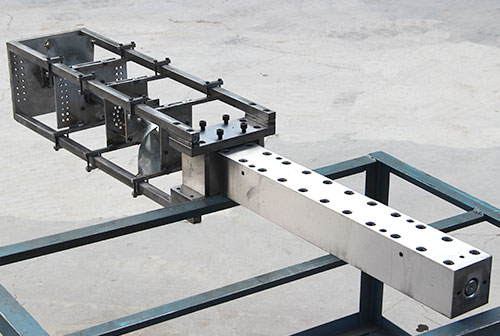

FRP pultrusion mold manufacturing process

Consequences of Mold Blockage in Fiberglass Pultrusion:

1. Production Disruptions: Mold blockages can bring the pultrusion process to a halt, causing significant delays in production. This can lead to missed deadlines, increased costs, and customer dissatisfaction.

2. Product Defects: If a blockage occurs during the pultrusion of a product, it can result in defects such as voids, uneven surfaces, or inconsistencies in material properties. These defects can render the product unusable or compromise its performance.

3. Increased Costs: Mold blockages not only disrupt production but also lead to increased costs associated with:

· Labor: Cleaning and repairing blocked molds require additional labor hours, increasing production costs.

· Materials: Blocked molds may necessitate the replacement of damaged mold components or wasted raw materials, further adding to costs.

· Downtime: Production downtime due to blockages translates into lost revenue and potential penalties for missed delivery commitments.

Preventing Mold Blockage in Fiberglass Pultrusion:

1. Resin Temperature Control: Maintain consistent resin temperatures within the recommended range to prevent premature gelation. Utilize temperature monitoring and control systems to ensure stability.

2. Resin Viscosity Management: Regularly test resin viscosity and adjust the formulation if necessary to achieve a consistent flow rate and prevent uneven curing.

3. Optimized Pultrusion Speed: Determine the optimal pultrusion speed based on the resin type, fiber characteristics, and mold design to ensure sufficient resin flow and prevent gelation within the mold.

4. Fiber Preparation and Handling: Implement strict fiber preparation procedures to remove contaminants and ensure clean fibers. Properly store and handle raw materials to minimize the introduction of debris.

5. Effective Mold Design: Employ well-designed molds with smooth surfaces, adequate drainage channels, and minimal dead zones to prevent fiber debris accumulation.

6. Regular Mold Cleaning: Establish a routine mold cleaning schedule to remove any accumulated debris, contaminants, or cured resin residues. Utilize appropriate cleaning methods and solvents suitable for the mold material.

7. Maintain a Clean Work Environment: Regularly clean the pultrusion area to minimize dust, dirt, and airborne contaminants that could contaminate the process. Implement proper material handling procedures and storage practices.

Conclusion:

Blockages in fiberglass pultrusion molds can have severe consequences for production efficiency, product quality, and overall costs. By understanding the root causes of these blockages and implementing preventive measures, manufacturers can ensure a smooth, efficient, and defect-free pultrusion process.

Additional Tips for Preventing Mold Blockage:

· Regular Mold Inspection: Regularly inspect molds for signs of wear, damage, or debris accumulation. Promptly address any issues to prevent blockages.

· Preventive Maintenance: Implement a preventive maintenance program for pultrusion equipment, including molds, guides, rollers, and resin dispensing systems. Regular maintenance can identify and address potential problems before they cause blockages.

· Training and Awareness: Provide training to pultrusion operators on the importance of mold cleanliness, proper fiber preparation, and efficient pultrusion techniques. Foster a culture of awareness and responsibility among employees to prevent blockages.

· Continuous Improvement: Continuously monitor the pultrusion process, identify potential blockages, and implement corrective actions. Utilize data analysis and quality control measures to refine processes and prevent blockages from recurring.

By adopting these preventive measures and maintaining a proactive approach, manufacturers can minimize the occurrence of mold blockages, ensuring a streamlined and cost-effective fiberglass pultrusion operation.

Remember, preventing mold blockages is not just about avoiding production disruptions; it's about maintaining product quality, reducing costs, and ensuring the long-term success of your fiberglass pultrusion business.

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data