Custom FRP Profiles

Custom FRP Profiles: The Versatile Choice for Industrial Applications

In the world of industrial materials, Fiber Reinforced Polymer (FRP) profiles have emerged as a game-changer. Custom FRP profiles, in particular, offer unparalleled versatility, making them the go-to choice for a wide range of industrial applications. From construction to chemical processing, these profiles provide a unique combination of strength, durability, and corrosion resistance that traditional materials like steel and aluminum simply cannot match.

What Are Custom FRP Profiles?

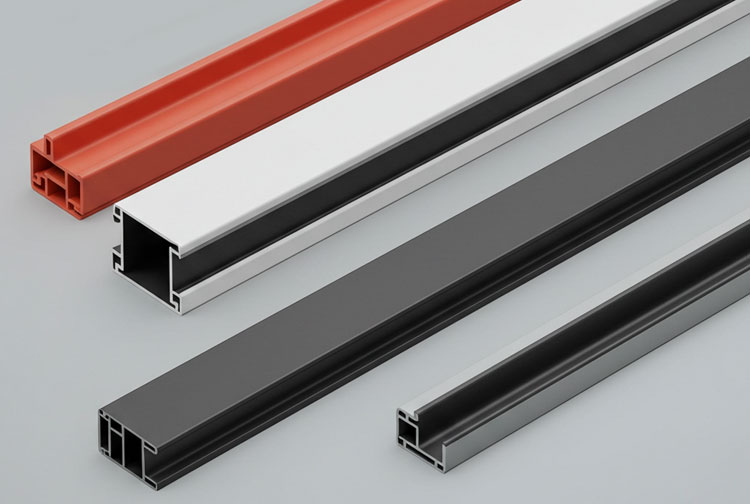

Custom FRP profiles are specially designed fiberglass reinforced polymer shapes that are tailored to meet specific industrial needs. These profiles are manufactured using a combination of high-strength fibers (such as glass, carbon, or aramid) and a polymer resin matrix. The result is a lightweight, yet incredibly strong material that can be customized into various shapes and sizes to fit precise application requirements.

Benefits of Custom FRP Profiles

-

Corrosion Resistance: One of the most significant advantages of custom FRP profiles is their exceptional resistance to corrosion. Unlike metals, FRP does not rust or corrode when exposed to harsh chemicals, moisture, or saltwater. This makes them ideal for use in environments such as chemical plants, wastewater treatment facilities, and marine applications.

-

Lightweight: FRP profiles are significantly lighter than traditional materials like steel and aluminum. This lightweight nature reduces transportation costs, eases installation, and minimizes the structural load on supporting frameworks.

-

High Strength-to-Weight Ratio: Despite their lightweight, custom FRP profiles offer a high strength-to-weight ratio. They can withstand heavy loads and harsh conditions without compromising on performance.

-

Durability: FRP materials are known for their long-lasting durability. They resist UV radiation, weathering, and impact, ensuring a longer service life with minimal maintenance.

-

Customizability: As the name suggests, custom FRP profiles can be tailored to meet specific design requirements. Whether you need a unique shape, size, or color, FRP profiles can be manufactured to exact specifications.

-

Electrical Insulation: FRP is an excellent electrical insulator, making it suitable for applications where electrical conductivity is a concern, such as in the electrical and telecommunications industries.

-

Thermal Insulation: FRP profiles also offer good thermal insulation properties, which can be beneficial in applications requiring temperature control.

Industrial Applications of Custom FRP Profiles

The versatility of custom FRP profiles makes them suitable for a wide range of industrial applications. Here are some of the most common uses:

-

Construction: In the construction industry, custom FRP profiles are used for structural components, such as beams, columns, and trusses. They are also used in building facades, bridges, and platforms due to their strength and corrosion resistance.

-

Chemical Processing: FRP profiles are widely used in chemical processing plants for equipment such as tanks, pipes, and ductwork. Their resistance to corrosive chemicals ensures long-term reliability and safety.

-

Water and Wastewater Treatment: In water and wastewater treatment facilities, FRP profiles are used for grating, handrails, and structural supports. Their resistance to moisture and chemicals makes them ideal for these environments.

-

Marine: The marine industry benefits from FRP profiles in the construction of boats, docks, and offshore platforms. Their resistance to saltwater corrosion and lightweight nature are particularly advantageous.

-

Electrical and Telecommunications: FRP profiles are used in the electrical and telecommunications industries for cable trays, ladder racks, and antenna supports. Their electrical insulation properties ensure safe and reliable performance.

-

Transportation: In the transportation sector, FRP profiles are used for lightweight structural components in vehicles, such as buses, trains, and trucks. Their durability and strength contribute to improved fuel efficiency and reduced maintenance costs.

-

Oil and Gas: The oil and gas industry utilizes FRP profiles for pipelines, walkways, and platforms in offshore and onshore facilities. Their resistance to harsh environmental conditions and corrosive substances is crucial in these applications.

Why Choose Custom FRP Profiles?

When it comes to industrial applications, the choice of material can significantly impact the success of a project. Custom FRP profiles offer a unique combination of properties that make them the versatile choice for a wide range of industries. Here are some reasons why you should consider custom FRP profiles for your next project:

-

Tailored Solutions: Custom FRP profiles can be designed to meet specific requirements, ensuring a perfect fit for your application. Whether you need a unique shape, size, or color, FRP profiles can be manufactured to exact specifications.

-

Cost-Effective: While the initial cost of FRP profiles may be higher than traditional materials, their long-term benefits, such as reduced maintenance and longer service life, make them a cost-effective choice.

-

Enhanced Performance: The unique properties of FRP, such as corrosion resistance, lightweight, and high strength, contribute to enhanced performance in various industrial applications.

-

Sustainability: FRP profiles are environmentally friendly, as they are made from recyclable materials and have a long service life, reducing the need for frequent replacements.

-

Ease of Installation: The lightweight nature of FRP profiles makes them easy to transport and install, reducing labor costs and installation time.

Conclusion

Custom FRP profiles are revolutionizing the industrial materials landscape with their versatility, durability, and performance. Whether you're in construction, chemical processing, marine, or any other industry, FRP profiles offer a reliable and cost-effective solution for your needs. Their ability to withstand harsh environments, resist corrosion, and provide long-lasting performance makes them the ideal choice for a wide range of applications.

By choosing custom FRP profiles, you're not only investing in a high-quality material but also ensuring the success and longevity of your industrial projects. So, the next time you're faced with a challenging industrial application, consider the versatile and reliable option of custom FRP profiles.

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data