FRP grating, also known as fiberglass reinforced plastic grating, has become an increasingly popular choice for walkways and platforms in a variety of industries. Composed of a resin matrix reinforced with fiberglass fibers, FRP grating offers a unique combination of properties that make it an ideal material for demanding applications. In this article, we will explore the advantages of FRP grating and why it is the preferred choice for many industries.

Understanding FRP Grating

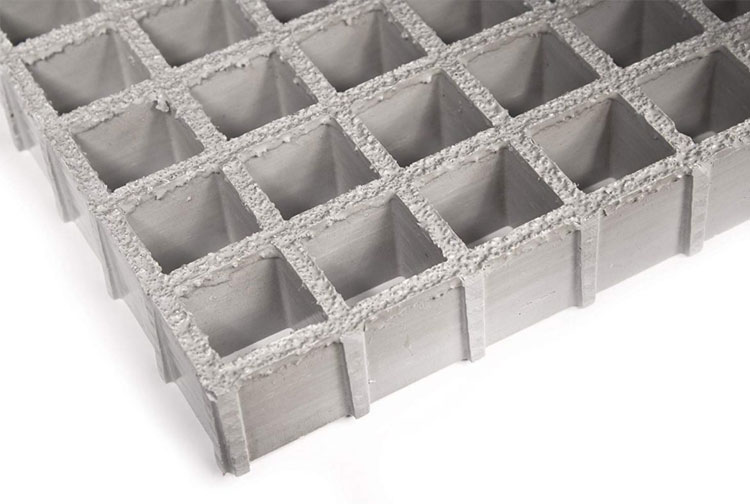

FRP grating is a composite material manufactured by combining fiberglass fibers with a thermosetting resin. This process results in a lightweight, strong, and corrosion-resistant product. The open grid structure of FRP grating allows for easy drainage, ventilation, and light transmission.

Advantages of FRP Grating

Corrosion Resistance: FRP grating is highly resistant to corrosion from a wide range of chemicals, acids, and salts, making it ideal for harsh environments such as chemical plants, wastewater treatment facilities, and marine applications.

Slip Resistance: The molded-in surface pattern of FRP grating provides excellent slip resistance, even in wet or oily conditions, ensuring the safety of personnel.

Lightweight: FRP grating is significantly lighter than traditional metal gratings, making it easier to handle, transport, and install.

Durability: FRP grating is extremely durable and can withstand heavy loads and impact. It is resistant to UV radiation, thermal shock, and fatigue.

Electrical Insulation: FRP grating is a non-conductive material, making it safe for use in electrically hazardous environments.

Low Maintenance: FRP grating requires minimal maintenance and does not rust or corrode, reducing long-term costs.

Customizable: FRP grating can be customized to meet specific requirements in terms of size, shape, and load-bearing capacity.

Applications of FRP Grating

Industrial Facilities: FRP grating is widely used in industrial facilities for walkways, platforms, and catwalks. Its corrosion resistance and slip resistance make it ideal for chemical processing plants, refineries, and food processing facilities.

Marine Applications: FRP grating is used extensively in marine applications such as docks, piers, and offshore platforms due to its resistance to saltwater and corrosion.

Wastewater Treatment: FRP grating is used in wastewater treatment plants for walkways, covers, and grating over tanks.

Food Processing: FRP grating is a hygienic choice for food processing facilities due to its non-porous surface and resistance to bacteria.

Commercial Buildings: FRP grating is used in commercial buildings for roofing, skylights, and flooring in areas that require durability and corrosion resistance.

Comparison to Traditional Materials

| Feature | FRP Grating | Steel Grating | Aluminum Grating |

|---|---|---|---|

| Corrosion Resistance | Excellent | Susceptible to rust | Susceptible to corrosion in certain environments |

| Slip Resistance | Excellent | Moderate | Moderate |

| Weight | Lightweight | Heavy | Lightweight |

| Maintenance | Low | High | Moderate |

| Cost | Moderate | Moderate | High |

Installation of FRP Grating

FRP grating is relatively easy to install and can be cut and drilled on-site. It can be secured to supporting structures using various fasteners, such as bolts, clips, or adhesives.

Conclusion

FRP grating offers a compelling combination of properties that make it an ideal choice for walkways and platforms in a wide range of applications. Its corrosion resistance, slip resistance, durability, and low maintenance requirements make it a cost-effective and long-lasting solution. Whether you are building a new facility or retrofitting an existing one, FRP grating is a versatile and reliable material that can enhance safety and productivity.

Additional Keywords: FRP grating applications, FRP grating benefits, FRP grating vs steel grating, FRP grating installation, FRP grating price, FRP grating manufacturers

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data