Fiberglass vs. Steel Unistrut Channel: A Comprehensive Comparison

When it comes to constructing sturdy and versatile support structures, unistrut channels are a popular choice among engineers and contractors. However, the decision between fiberglass and steel unistrut channels can be challenging due to the unique properties and applications of each material. In this article, we will delve into the key differences between fiberglass and steel unistrut channels, helping you determine the best option for your specific project.

Understanding Unistrut Channels

Unistrut channels are versatile metal or fiberglass framing members that provide a flexible and efficient way to support various loads, including piping, conduit, and equipment. They are widely used in industrial, commercial, and residential applications.

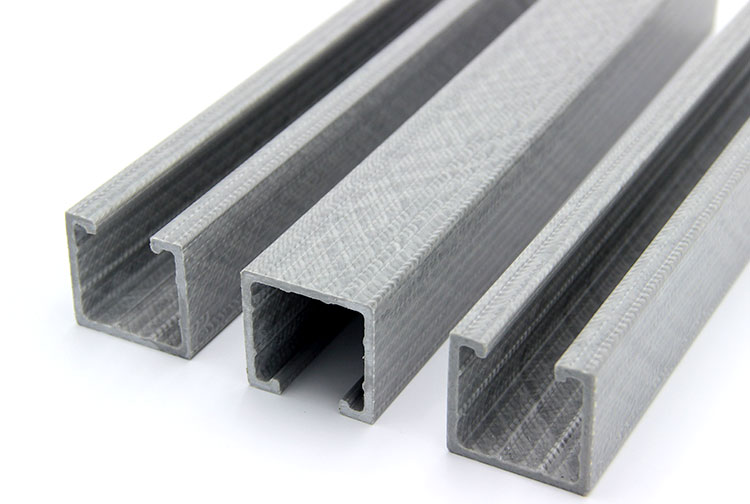

Fiberglass Unistrut Channels

Fiberglass unistrut channels are made from a composite material consisting of fiberglass reinforced with a resin binder. This construction offers several advantages:

Corrosion Resistance: Fiberglass is highly resistant to corrosion, making it ideal for applications in harsh environments such as chemical plants, wastewater treatment facilities, and marine environments.

Lightweight: Fiberglass channels are significantly lighter than steel channels, reducing installation time and effort.

Non-Conductive: Fiberglass is a non-conductive material, making it safe for use in electrical applications and environments where electrical conductivity is a concern.

Dimensional Stability: Fiberglass channels are dimensionally stable, meaning they are less susceptible to expansion or contraction due to temperature changes.

Chemical Resistance: Fiberglass is resistant to a wide range of chemicals, making it suitable for use in corrosive environments.

Steel Unistrut Channels

Steel unistrut channels are made from carbon steel, which offers a different set of properties:

Strength: Steel channels are generally stronger than fiberglass channels, making them suitable for heavy-duty applications.

Versatility: Steel channels are available in a wide range of sizes and configurations, offering greater flexibility in design.

Cost-Effective: Steel channels are often more cost-effective than fiberglass channels, especially for large-scale projects.

Conductivity: Steel is a conductive material, which can be a consideration in electrical applications.

Corrosion Susceptibility: Steel is susceptible to corrosion, especially in harsh environments, and may require additional coatings or treatments.

Comparison Table

| Feature | Fiberglass Unistrut | Steel Unistrut |

| Corrosion Resistance | Excellent | Moderate (can be improved with coatings) |

| Weight | Lightweight | Heavy |

| Strength | Good | Excellent |

| Conductivity | Non-conductive | Conductive |

| Cost | Higher | Lower |

| Chemical Resistance | Excellent | Moderate |

| Dimensional Stability | Excellent | Good |

Choosing the Right Material

The best choice between fiberglass and steel unistrut channels depends on the specific requirements of your project. Consider the following factors when making your decision:

Environment: If the application involves exposure to corrosive chemicals, high humidity, or saltwater, fiberglass is the preferred choice.

Load Capacity: For heavy-duty applications requiring high load-bearing capacity, steel may be more suitable.

Electrical Considerations: If electrical conductivity is a concern, fiberglass is the safer option.

Cost: If cost is a primary concern, steel may be more affordable.

Installation: The weight and ease of installation can also influence your decision.

Applications

Fiberglass:

Chemical processing plants, Wastewater treatment facilities, Marine environments, Electrical installations, Cleanrooms

Steel:

General construction, Industrial facilities, Commercial buildings, Mechanical applications

Conclusion

Both fiberglass and steel unistrut channels offer unique advantages and are well-suited for a wide range of applications. By carefully considering the factors discussed above, you can select the most appropriate material for your project. If you require maximum corrosion resistance, lightweight construction, and non-conductivity, fiberglass is the ideal choice. However, if strength, cost, and a wide range of configurations are your primary concerns, steel may be the better option.

Additional Considerations

Hybrid Systems: In some cases, a combination of fiberglass and steel unistrut channels may be used to create a hybrid system that takes advantage of the best properties of both materials.

Coatings and Finishes: Steel channels can be coated or galvanized to improve their corrosion resistance and extend their lifespan.

Installation Methods: The installation methods for fiberglass and steel channels may vary slightly, so it is important to consult the manufacturer's guidelines.

By carefully evaluating your project requirements and considering the advantages and disadvantages of each material, you can make an informed decision and select the unistrut channel that best suits your needs.

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data