Pultruded Fiberglass FRP Beams

Pultruded Fiberglass FRP Beams for Structural Applications: A Wood Alternative

In the world of construction and infrastructure, selecting the right materials for structural applications is crucial for ensuring safety, durability, and cost-effectiveness. Pultruded fiberglass FRP beams have emerged as a compelling alternative to traditional wood beams, offering a unique combination of properties that make them suitable for a wide range of projects. In this comprehensive guide, we will delve into the world of pultruded fiberglass FRP beams, exploring their advantages, applications, and why they are becoming a preferred choice for structural engineers and architects.

Understanding Pultruded Fiberglass FRP Beams

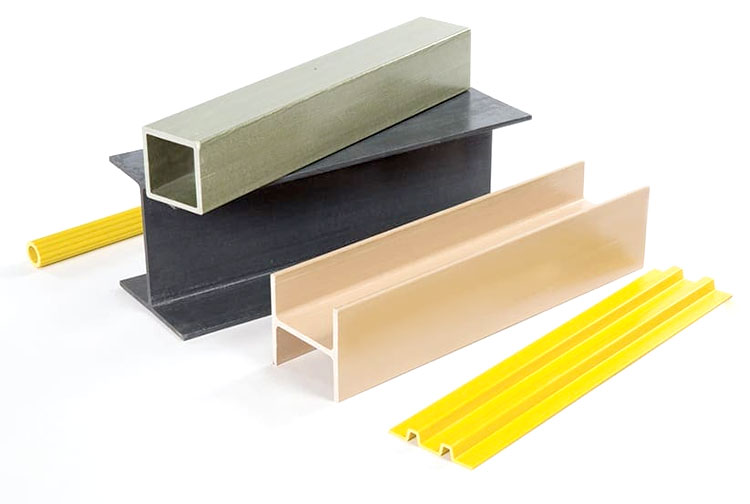

Pultruded fiberglass FRP beams are structural shapes manufactured through a pultrusion process. This process involves pulling continuous strands of fiberglass rovings and mats through a resin bath and then curing them in a heated die. The resulting profile exhibits exceptional strength, dimensional stability, and corrosion resistance.

Key Properties of Pultruded Fiberglass FRP Beams

- High Strength-to-Weight Ratio: Pultruded fiberglass FRP beams possess a high strength-to-weight ratio, making them significantly lighter than steel beams while maintaining comparable or even superior strength.

- Corrosion Resistance: Unlike steel beams that are susceptible to rust and corrosion, pultruded fiberglass FRP beams are inherently resistant to a wide range of chemicals, acids, and alkalis.

- Dimensional Stability: Pultruded fiberglass FRP beams exhibit excellent dimensional stability, meaning they are resistant to warping, twisting, and deformation under load or environmental changes.

- Design Flexibility: Pultruded fiberglass FRP beams can be manufactured in a variety of shapes and sizes, allowing for customized designs to meet specific structural requirements.

- Durability: Pultruded fiberglass FRP beams are highly durable and can withstand harsh environmental conditions, including UV radiation, extreme temperatures, and moisture.

Advantages of Pultruded Fiberglass FRP Beams over Wood Beams

- Long-Term Cost Savings: While the initial cost of pultruded fiberglass FRP beams may be slightly higher than wood beams, their long lifespan, low maintenance requirements, and resistance to rot and decay result in significant cost savings over time.

- Reduced Maintenance: Unlike wood beams that require regular painting, sealing, or staining to prevent rot and insect damage, pultruded fiberglass FRP beams require minimal maintenance, saving time and money.

- Consistent Quality: Pultruded fiberglass FRP beams are manufactured under controlled conditions, ensuring consistent quality and performance across all beams.

- Faster Installation: The lightweight nature of pultruded fiberglass FRP beams simplifies handling and installation, reducing labor costs and project timelines.

- Environmental Friendliness: Pultruded fiberglass FRP beams can be manufactured from recycled materials, reducing their environmental impact compared to wood beams that require cutting down trees.

Applications of Pultruded Fiberglass FRP Beams

Pultruded fiberglass FRP beams find widespread application in various structural projects, including:

- Bridges: Pultruded fiberglass FRP beams are used in pedestrian bridges, bridge decks, and other bridge components due to their strength, lightweight properties, and corrosion resistance.

- Buildings: Pultruded fiberglass FRP beams are utilized in structural framing, roof supports, and wall systems in commercial and residential buildings.

- Docks and Piers: Pultruded fiberglass FRP beams are ideal for marine structures like docks and piers due to their resistance to saltwater corrosion and marine borers.

- Industrial Platforms and Walkways: Pultruded fiberglass FRP beams are used in industrial platforms, walkways, and mezzanines due to their strength, durability, and slip resistance.

- Cooling Towers: Pultruded fiberglass FRP beams are employed in cooling tower structures due to their resistance to moisture, chemicals, and high temperatures.

Pultruded Fiberglass FRP Beams vs. Wood Beams: A Comparative Analysis

| Feature | Pultruded Fiberglass FRP Beams | Wood Beams |

|---|---|---|

| Strength-to-Weight Ratio | High | Moderate |

| Corrosion Resistance | Excellent | Susceptible to rot and decay |

| Dimensional Stability | Excellent | Prone to warping and twisting |

| Maintenance | Low | High |

| Lifespan | Long | Shorter |

| Cost | Higher initial cost but lower long-term cost | Lower initial cost but higher long-term cost |

| Environmental Impact | Lower | Higher |

Conclusion

Pultruded fiberglass FRP beams offer a compelling alternative to traditional wood beams in structural applications, providing a unique combination of strength, lightweight properties, corrosion resistance, and design flexibility. Their advantages in terms of long-term cost savings, reduced maintenance, and environmental friendliness make them an increasingly popular choice for structural engineers and architects. As the demand for sustainable and durable construction materials continues to grow, pultruded fiberglass FRP beams are poised to play a significant role in shaping the future of infrastructure.

Additional Considerations

- Design Codes and Standards: Ensure that the design and installation of pultruded fiberglass FRP beams comply with relevant building codes and standards.

- Fire Safety: Consider the fire safety requirements of the project and select pultruded fiberglass FRP beams with appropriate fire ratings.

- Installation Expertise: Engage experienced contractors familiar with the installation of pultruded fiberglass FRP beams to ensure proper installation and structural integrity.

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data