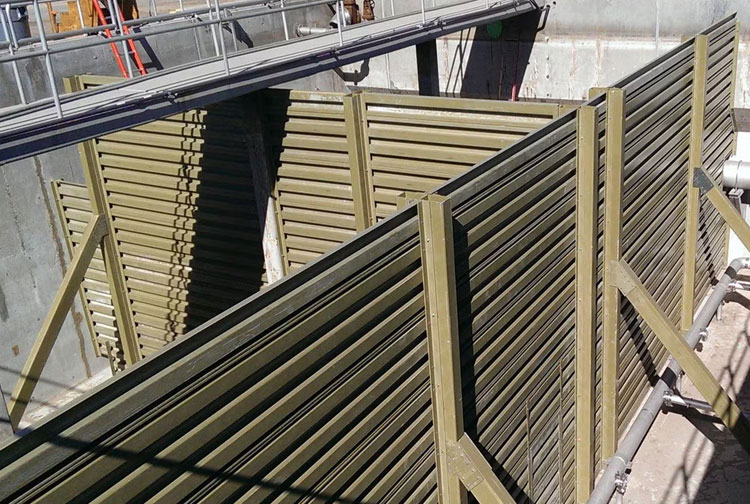

FRP Baffle Wall in Wastewater Treatment

The Future of Wastewater Management with FRP Baffle Walls

Wastewater management is a critical challenge for industries and municipalities, particularly in rapidly developing regions like Southeast Asia. With growing urbanization and industrial activity, the need for efficient, durable, and sustainable solutions has never been greater. This is where the FRP baffle wall steps in as a transformative innovation. Made from Fiber Reinforced Plastic, these baffle walls are redefining how wastewater treatment plants operate by improving flow control, enhancing sedimentation, and ensuring long-term reliability. In this article, we’ll explore the unique advantages of FRP baffle walls and their impact on modern wastewater management systems.

What Makes FRP Baffle Walls Stand Out?

Unlike traditional materials such as concrete or steel, FRP baffle walls offer a combination of lightweight design and exceptional durability. One of their most significant advantages is their corrosion resistance, which makes them ideal for the harsh environments found in wastewater treatment facilities. The wastewater management baffle wall made from FRP can withstand exposure to chemicals, moisture, and organic compounds without degrading, ensuring a longer lifespan and reduced maintenance needs. This is particularly valuable in Southeast Asia, where high humidity and tropical conditions can accelerate the deterioration of conventional materials.

Interested in a solution that lasts? Explore our corrosion-resistant FRP baffle walls designed for tough environments.

Optimizing Flow and Efficiency in Treatment Plants

The primary function of a baffle wall in wastewater management is to control the flow of water, ensuring proper sedimentation and separation of solids. FRP baffle walls excel in this role by providing precise flow direction and minimizing turbulence. Their smooth surfaces reduce the buildup of debris, which can clog systems and reduce efficiency. In a treatment plant in Thailand, for example, the installation of corrosion-resistant FRP baffles led to a noticeable improvement in sedimentation rates, allowing the facility to process larger volumes of wastewater without compromising quality.

Key Benefits of FRP Baffle Walls

Let’s break down the core advantages of using FRP baffle walls in wastewater management:

- Corrosion Resistance: Immune to rust and chemical degradation, making them ideal for handling wastewater with varying pH levels.

- Lightweight Design: Easier to transport and install compared to heavy concrete or steel alternatives, reducing setup time and labor costs.

- Customizable Shapes: FRP baffle walls can be molded into various shapes and sizes to fit the specific needs of a treatment plant.

- Low Maintenance: Their durable nature means fewer repairs and replacements, saving time and resources in the long run.

Comparing FRP Baffle Walls to Other Materials

To highlight the superiority of FRP baffle walls, here’s a comparison with other commonly used materials in wastewater management:

| Material | Corrosion Resistance | Weight | Lifespan | Maintenance Needs |

|---|---|---|---|---|

| FRP | High | Lightweight | Long | Low |

| Steel | Low | Heavy | Moderate | High |

| Concrete | Moderate | Very Heavy | Long | Moderate |

This comparison underscores why FRP baffle walls are becoming the preferred choice for wastewater management systems, particularly in challenging environments.

Real-World Applications in Southeast Asia

In Southeast Asia, FRP baffle walls are making a tangible difference in wastewater treatment. A municipal plant in the Philippines recently upgraded its facility with FRP baffle walls, resulting in improved flow control and reduced energy consumption. Similarly, a factory in Vietnam that processes industrial wastewater reported fewer maintenance shutdowns after switching to FRP, thanks to the material’s resistance to corrosive byproducts. These examples demonstrate the practical benefits of adopting FRP baffle walls in real-world settings.

Sustainability and Environmental Impact

FRP baffle walls also align with the growing emphasis on sustainability in Southeast Asia. Their long lifespan reduces the need for frequent replacements, minimizing waste. Additionally, the lightweight nature of FRP reduces the energy required for transportation and installation, contributing to a lower carbon footprint. For industries aiming to meet environmental regulations while maintaining operational efficiency, FRP baffle walls offer a win-win solution.

Why Invest in FRP Baffle Walls?

The FRP baffle wall is more than just a component—it’s a strategic investment for wastewater management systems. Its ability to resist corrosion, optimize flow, and reduce maintenance makes it an invaluable asset for treatment plants, factories, and municipalities. By choosing FRP, businesses in Southeast Asia can improve their operations while contributing to a more sustainable future.

Ready to upgrade your wastewater management system? Visit our FRP baffle walls collection to find the perfect solution for your needs.

Conclusion

FRP baffle walls are revolutionizing wastewater management in Southeast Asia, offering a durable, efficient, and sustainable solution for modern challenges. As industries continue to grow and environmental standards tighten, the adoption of FRP baffle walls will likely accelerate. By integrating these innovative walls into their systems, businesses can achieve better performance, lower costs, and a reduced environmental impact. Embrace the future of wastewater management with FRP baffle walls today!

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data