In the realm of construction and industrial applications, the need for strong, durable, and corrosion-resistant support systems is paramount. FRP Unistrut, also known as fiberglass Unistrut, has emerged as a compelling solution, offering a robust non-metallic alternative to traditional steel Unistrut framing systems. Let's explore the world of FRP Unistrut, unraveling its unique properties, applications, and advantages that make it a versatile and sought-after choice in various industries.

Understanding FRP Unistrut:

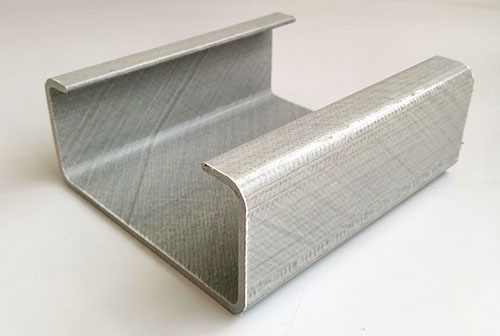

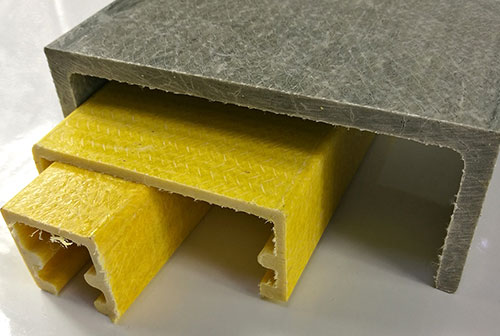

FRP Unistrut is a channel-based framing system constructed entirely from non-metallic, corrosion-resistant resins. This unique composition sets it apart from traditional steel Unistrut, which is susceptible to rust and corrosion in harsh environments.

Properties of FRP Unistrut:

1- Corrosion Resistance: The fiberglass construction of FRP Unistrut provides exceptional resistance to rust, acids, alkalis, and other corrosive substances, making it ideal for applications where steel might deteriorate.

2- Lightweight: Compared to steel Unistrut, FRP Unistrut is significantly lighter, simplifying handling, transportation, and installation, especially for large-scale projects.

3- Strength: Despite its lightweight nature, FRP Unistrut boasts remarkable strength and load-bearing capacity, capable of supporting substantial weight and ensuring structural integrity.

4- Non-Conductivity: Fiberglass, the primary component of FRP Unistrut, is an excellent electrical insulator, making it suitable for applications where electrical conductivity could pose a hazard.

5- Versatility: FRP Unistrut is available in a wide range of channel sizes and is compatible with a diverse array of accessories, including nuts, pipe clamps, and hangers, catering to various construction and framing needs.

Applications of FRP Unistrut:

FRP Unistrut's exceptional corrosion resistance, lightweight properties, and non-conductive nature make it a prime choice for applications in challenging environments:

1- Wastewater Treatment Facilities: In wastewater treatment plants, FRP Unistrut is widely used for constructing pipe racks, walkways, and support structures, as it can withstand exposure to harsh chemicals and corrosive wastewater.

FRP Unistrut wastewater treatment facilities

2- Chemical Processing Plants: In chemical processing environments, FRP Unistrut is employed for building support structures, pipe racks, and platforms, as it can resist the damaging effects of acids, alkalis, and other aggressive chemicals.

3- Refineries: Refineries, with their inherent exposure to corrosive substances and hazardous materials, rely on FRP Unistrut for constructing pipe racks, walkways, and support structures, ensuring safety and longevity.

4- Marine Environments: In marine environments, FRP Unistrut is utilized for building docks, piers, and support structures, as it can withstand the corrosive effects of saltwater and harsh weather conditions.

5- Food Processing Facilities: In food processing plants, FRP Unistrut is employed for constructing conveyor systems, support structures, and walkways, as it meets hygiene standards and resists corrosion from food substances.

Advantages of FRP Unistrut over Steel Unistrut:

1- Superior Corrosion Resistance: FRP Unistrut's non-metallic construction provides unmatched corrosion resistance, extending its lifespan and eliminating the need for frequent maintenance or replacement.

2- Lightweight Design: The lightweight nature of FRP Unistrut simplifies handling, transportation, and installation, reducing labor costs and expediting project completion.

3- Electrical Safety: FRP Unistrut's non-conductive properties make it ideal for applications where electrical hazards are a concern, minimizing the risk of electrical shocks and ensuring safety.

4- Versatility in Harsh Environments: FRP Unistrut's ability to withstand harsh chemicals, extreme temperatures, and UV radiation makes it suitable for a wider range of environments compared to steel Unistrut.

5- Long-Term Cost-Effectiveness: While the initial cost of FRP Unistrut may be higher than steel Unistrut, its durability, low maintenance requirements, and extended lifespan make it a more cost-effective choice over the long term

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data