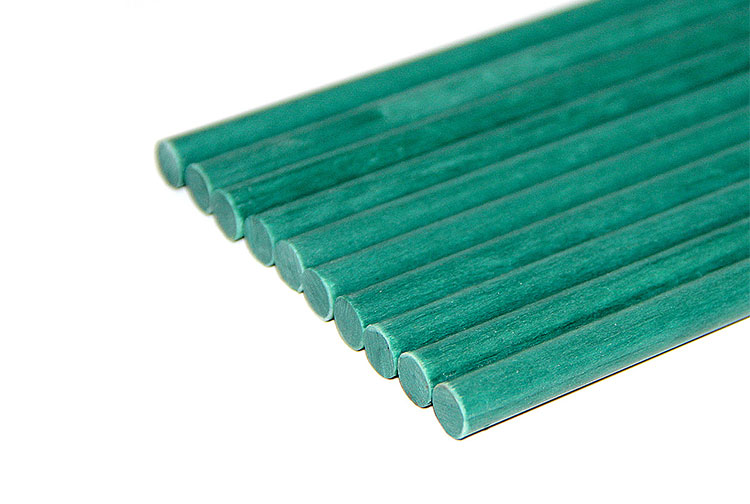

What Are Fiberglass Dowel Rods?

Fiberglass dowel rods are cylindrical rods made from a composite material combining glass fibers and resin. This combination results in a lightweight, strong, and highly durable material resistant to corrosion, moisture, and extreme temperatures. Fiberglass dowels are commonly used in construction, marine applications, outdoor furniture, and DIY projects due to their versatility and resilience.

What Are Wood Dowel Rods?

Wood dowel rods are solid cylindrical pieces crafted from various types of wood, such as oak, birch, pine, or maple. They are widely used in furniture making, woodworking, crafting, and structural applications. Wood dowels are valued for their natural aesthetic, affordability, and ease of customization through cutting, sanding, or staining.

Key Comparison Factors

To determine which material is better for your project, let’s dive into a detailed comparison of fiberglass dowel rods and wood dowel rods across several critical factors.

1. Durability and Strength

Fiberglass Dowel Rods: Fiberglass is renowned for its exceptional strength-to-weight ratio. It resists bending, cracking, and breaking under stress, making it ideal for high-load applications. Additionally, fiberglass is impervious to rust, rot, and corrosion, ensuring longevity in harsh environments like marine or outdoor settings.

Wood Dowel Rods: Wood dowels are strong but less durable than fiberglass in challenging conditions. They are prone to splitting, warping, or rotting when exposed to moisture or temperature fluctuations. Hardwoods like oak offer better durability than softwoods like pine, but they still fall short of fiberglass in extreme environments.

Verdict: Fiberglass dowel rods win for durability, especially in outdoor or high-stress applications.

2. Weight

Fiberglass Dowel Rods: Fiberglass is significantly lighter than most woods, making it easier to handle and transport. This lightweight nature is advantageous for projects requiring portability or minimal structural weight, such as kites, model airplanes, or lightweight furniture.

Wood Dowel Rods: Wood dowels are heavier, particularly when made from dense hardwoods. While this added weight can provide stability in certain applications, it can be a drawback for projects where minimizing weight is a priority.

Verdict: Fiberglass dowel rods are the better choice for lightweight applications.

3. Cost

Fiberglass Dowel Rods: Fiberglass dowels tend to be more expensive due to the manufacturing process and material costs. However, their long lifespan and low maintenance requirements can offset the initial investment, especially for projects requiring durability.

Wood Dowel Rods: Wood dowels are generally more affordable, especially softwood varieties like pine. They are a cost-effective option for indoor projects or temporary structures where longevity is not a primary concern.

Verdict: Wood dowel rods are more budget-friendly for cost-conscious projects.

4. Environmental Impact

Fiberglass Dowel Rods: The production of fiberglass involves energy-intensive processes and non-renewable materials, contributing to a higher environmental footprint. However, their durability means fewer replacements, reducing long-term waste.

Wood Dowel Rods: Wood is a renewable resource, and responsibly sourced wood dowels (e.g., FSC-certified) have a lower environmental impact. However, deforestation and chemical treatments for preservation can negate some of these benefits.

Verdict: Wood dowel rods have an edge for eco-conscious projects, provided they are sustainably sourced.

5. Versatility and Applications

Fiberglass Dowel Rods: Fiberglass dowels excel in applications requiring weather resistance and strength. Common uses include:

- Marine structures (e.g., boat frames, dock supports)

- Outdoor furniture and garden stakes

- Lightweight structural supports in construction

- DIY projects like kites, model rockets, or tent poles

Wood Dowel Rods: Wood dowels are highly versatile for indoor and aesthetic applications, such as:

- Furniture joinery (e.g., chairs, tables)

- Decorative crafts and woodworking projects

- Temporary structures or prototypes

- Educational models or toys

Verdict: Both materials are versatile, but fiberglass is better for outdoor and high-durability needs, while wood shines in aesthetic and indoor applications.

6. Ease of Customization

Fiberglass Dowel Rods: Cutting and shaping fiberglass requires specialized tools (e.g., diamond-tipped saws) due to its hardness. It cannot be easily stained or painted, limiting aesthetic customization.

Wood Dowel Rods: Wood is easy to cut, sand, stain, or paint, making it highly customizable for aesthetic or functional purposes. This ease of modification is a significant advantage for crafters and woodworkers.

Verdict: Wood dowel rods are superior for projects requiring customization.

Comparison Table: Fiberglass vs. Wood Dowel Rods

| Feature | Fiberglass Dowel Rods | Wood Dowel Rods |

|---|---|---|

| Durability | High (resists rot, corrosion) | Moderate (prone to rot, warping) |

| Weight | Lightweight | Heavier |

| Cost | Higher | Lower |

| Environmental Impact | Higher footprint | Lower (if sustainably sourced) |

| Customization | Limited | High (easy to cut, stain) |

| Best Applications | Outdoor, marine, high-stress | Indoor, furniture, crafts |

Real-World Applications

To illustrate the practical differences, let’s explore some real-world scenarios:

Scenario 1: Building a Garden Trellis

For a garden trellis exposed to rain and sun, fiberglass dowel rods are ideal due to their weather resistance and durability. They won’t rot or warp, ensuring the trellis lasts for years. Wood dowels, while cheaper, may require frequent replacement or chemical treatments.

Scenario 2: Crafting a Wooden Toy

For a child’s wooden toy, wood dowel rods are the better choice. They can be easily cut, sanded, and painted to create a smooth, colorful product. Fiberglass would be overkill and difficult to customize for this purpose.

Scenario 3: Marine Dock Supports

In a marine environment, fiberglass dowel rods shine. Their resistance to saltwater corrosion makes them perfect for dock supports or boat frames, where wood would quickly deteriorate.

Which Should You Choose?

The choice between fiberglass dowel rods and wood dowel rods depends on your project’s specific requirements:

- Choose Fiberglass Dowel Rods if: You need a lightweight, durable material for outdoor, marine, or high-stress applications. They’re worth the investment for long-term projects where maintenance is a concern.

- Choose Wood Dowel Rods if: You’re working on a budget, need easy customization, or are creating indoor or aesthetic projects like furniture or crafts.

For hybrid projects, you might even combine both materials—using fiberglass for structural supports and wood for decorative elements.

Tips for Working with Fiberglass and Wood Dowel Rods

Fiberglass Dowel Rods:

- Use proper safety gear (e.g., masks, gloves) when cutting to avoid inhaling fibers.

- Invest in high-quality cutting tools for clean, precise cuts.

- Store in a dry place to maintain integrity, though they’re highly resistant to environmental damage.

Wood Dowel Rods:

- Seal or treat wood dowels for outdoor use to prevent rot.

- Use a fine-grit sandpaper for smooth finishes before staining or painting.

- Check for knots or imperfections that could weaken the rod.

Where to Buy Fiberglass and Wood Dowel Rods

Fiberglass dowel rods are available from industrial suppliers, online retailers like Amazon, or specialty stores for composites. Wood dowel rods are widely available at hardware stores (e.g., Home Depot, Lowe’s), craft stores, or online marketplaces. Always compare prices and check for bulk discounts if you need large quantities.

Conclusion

Both fiberglass dowel rods and wood dowel rods have their place in the world of DIY, crafting, and construction. Fiberglass offers unmatched durability and weather resistance, making it ideal for outdoor and high-performance applications. Wood, on the other hand, provides affordability, ease of customization, and a natural aesthetic perfect for indoor and decorative projects. By understanding your project’s needs—durability, cost, weight, or environmental impact—you can make an informed decision that ensures success.

Have a specific project in mind? Share your thoughts in the comments below, and let us know whether you’re Team Fiberglass or Team Wood!

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data