In industrial applications, choosing the right flooring and grating materials can make a significant difference in terms of durability, safety, and overall cost-effectiveness. Steel grating has traditionally been a popular choice due to its strength and stability. However, in recent years, FRP grating (Fiberglass Reinforced Plastic grating) has gained attention as a powerful steel grating alternative. With its unique features and benefits, FRP grating has become a top choice for many industries, from petrochemical plants to food processing facilities.

This article will explore why FRP grating, which often utilizes fiberglass profiles, is a smart choice for both new constructions and retrofit projects. We will examine its many advantages, including its strength, resistance to corrosion, lightweight properties, and cost-effectiveness.

What is FRP Grating?

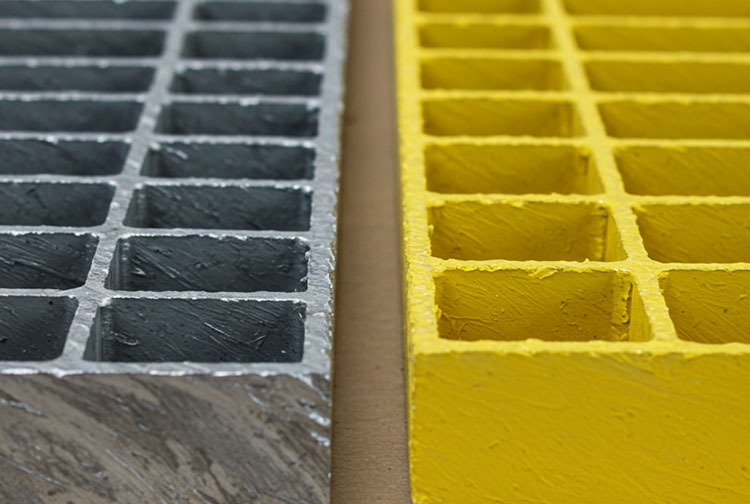

FRP grating is a type of grating material made by combining fiberglass reinforcement with resin. The fiberglass strands provide strength and durability, while the resin offers corrosion resistance and flexibility. Unlike steel grating, which can corrode, rust, and require regular maintenance, fiberglass grating stands up to the elements, providing a long-lasting and low-maintenance solution.

At the core of FRP grating is the fiberglass profile, which plays a crucial role in the material's strength and performance. These profiles are carefully engineered to deliver optimal strength-to-weight ratios while maintaining high resistance to harsh chemicals, extreme weather conditions, and heavy foot or vehicle traffic.

Why Choose FRP Grating Over Steel Grating?

While steel grating has been a staple in industrial flooring, it comes with some inherent disadvantages, especially when it comes to corrosion. Here are some key reasons why FRP grating is a superior alternative:

- Corrosion Resistance: Steel grating, while strong, is prone to rust and corrosion when exposed to moisture, chemicals, or saltwater. Over time, this can lead to expensive repairs or replacements. FRP grating is completely resistant to corrosion, making it ideal for industries such as chemical processing, wastewater treatment, marine applications, and more.

- Lightweight and Easy to Install: FRP grating is significantly lighter than steel grating, making it easier and less expensive to transport and install. The lightweight nature of fiberglass profiles reduces labor costs and minimizes the need for heavy equipment. The ease of installation also contributes to quicker project timelines.

- Enhanced Safety: Safety is always a priority in industrial environments, and FRP grating offers significant safety advantages over steel. The fiberglass profile is naturally slip-resistant, reducing the likelihood of accidents due to slippery surfaces, particularly in wet or oily conditions. Many FRP gratings come with textured surfaces that provide excellent traction underfoot.

- Cost-Effective: Although the upfront cost of FRP grating may be higher than steel in some cases, the total cost of ownership is lower. This is due to its low maintenance requirements, extended lifespan, and resistance to costly issues like rust and corrosion.

Applications of FRP Grating

FRP grating has become a preferred choice in a variety of industries. Here are some of the most common applications:

- Chemical and Petrochemical Plants: In chemical processing plants, FRP grating provides a high level of resistance to corrosive chemicals and extreme temperatures. It is widely used in floors, walkways, and platforms where safety and durability are paramount.

- Wastewater Treatment Facilities: FRP grating is ideal for use in wastewater treatment plants because of its resistance to water, moisture, and chemicals. It is commonly used for access walkways, drainage covers, and platform systems in these environments.

- Marine Applications: Marine environments are tough on materials, and steel grating can quickly corrode due to saltwater exposure. Fiberglass grating, on the other hand, remains unaffected by saltwater, making it the perfect solution for docks, piers, and boat ramps.

- Food Processing and Pharmaceutical Industries: The non-corrosive nature of FRP grating makes it an excellent choice for food processing plants, where hygiene is a priority. The material is easy to clean and sanitize, preventing the buildup of harmful substances and bacteria.

Benefits of Using Fiberglass Profiles in FRP Grating

- Strength and Durability: Fiberglass is known for its exceptional strength-to-weight ratio. The fiberglass profile ensures that FRP grating is both lightweight and strong, providing long-lasting support for industrial applications.

- Customizable: Fiberglass profiles can be easily molded and customized to meet specific design requirements. Whether it's a custom shape, size, or load-bearing specification, FRP grating can be engineered to meet the unique needs of each application.

- UV Resistance: Fiberglass grating is also resistant to UV radiation, making it suitable for outdoor applications. Over time, steel grating can deteriorate when exposed to sunlight, but FRP grating maintains its structural integrity and appearance.

Conclusion

FRP grating is rapidly becoming the preferred alternative to traditional steel grating in many industries due to its corrosion resistance, lightweight nature, enhanced safety, and overall cost-effectiveness. The use of fiberglass profiles in these grating systems enhances their durability and makes them ideal for use in harsh

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data